|

Product Details:

|

| Type: | Packaging Machine | Condition: | New |

|---|---|---|---|

| Application: | Applying To Die-cutting, Creasing, And Cold Embossing For Cartons, Paper Boxes And Paper Labels, Etc. | Packaging Type: | Case |

| Packaging Material: | Wood | Automatic Grade: | Automatic |

| Voltage: | 380V | Power: | 12.1KW |

| Place Of Origin: | Guangdong, China (Mainland) | Brand Name: | Wellmark |

| Model Number: | WM-1060 | Dimension(L*W*H): | 4500×1870×2000mm |

| Weight: | 11Ton | After-sales Service Provided: | Engineers Available To Service Machinery Overseas |

| Max.Die-cutting Speed: | 8000sheets/h | ||

| Highlight: | auto die cutting machine,die cutting and creasing machine,automatic die cutter |

||

Automatic Die-Cutting and Creasing Machine for Paper and Paperboard

Product Description

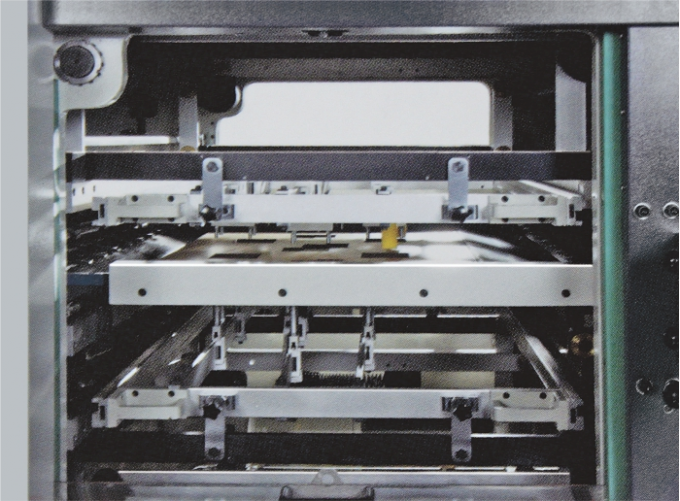

WM-920 Automatic die-cutting Machine is an ideal equipment to die cut and crease the paper, paper board packing material. It is easy to operate the machine with man machine interface with displaying the breakdown and frame locking system, digital displaying up-down of mold pressing. The cooling system of oil circulation decrease difference of hot and cold part of machine so as to reduce the number of rejects and extend the machine service life. Main electrical components are all world wide famous brands, Industry cooling system ensure the electric component durable and steady performance.

Technical Prameters

| Model | WM-920 |

| Max. Die-cutting Speed | 8000 sheets/h |

| Die-cutting Precision | ±0.1mm |

| Max. Die-cutting Pressure | 200T |

| Max. Paper Size | 920×670mm |

| Min. Paper Size | 360×320mm |

| Max. Die-cutting Size | 910×660mm |

| Cardboard | 80-2000g/㎡ |

| Corrugated paper | ≤5mm (max. thickness) |

| Total Power | 12.1KW |

| Weight | 11T |

| Dimensions | 4500×1870×2000mm |

Product Features

(1) Adopt nodular cast iron-QT500-7, the mainframe wallboard casting by special technology process, thus featuring by high strength, never deformation and ensure the safety of the mainframe wallboard.

(2) Adopt Taiwan-imported intermittent mechanism to ensure that the machine operates accurately and reduce the occurrence of failure rate.

(3) The whole machine all uses SKFNSK imported original bearing.

(4) The whole machine uses original parts imported from France Schneider, and Japanese OMRON, etc.

(5) Key parts of teeth row are imported from Japan.

(6) Die cutting accuracy reach to ±0.1mm, and the highest speed of machine reaches 7500 sheets/hours.

(7) The craft shaft is adopts Germany Ni-Cr-Mo metal steel, with high precision and will never deforms.

(8) Use the centerline positioning system to realize fast plate changing of worksheet.

(9) Die-cutting plate frame adopts auxiliary plate-installation device, to realize different of model machines can be use universal die-cutting plate.

(10) Equip with touch-screen operation interface in both Chinese and English.

Machine Characteristics

1. Complete design, accurate installation, high stability, high security, low noise.

2. Adopt worm, worm gear, crankshaft transmission, high cutting pressure, high durability.

3. High precision intermittent mechanism, high cutting precision, running steadily.

4. Adopt European technology feeder, suction adjustable, steadily, precise, good paper applicability.

5. Non-stop feeding, pre-stacking and delivery device can shorten the auxiliary time, improve the efficiency.

Further Features

1. High performance servo control system with high stability and anti-interference performance.

2. Static elimination device to make paper smooth and accurate.

3. Automatic Stripping device.

4. Four Air intake and four air outlet in paper feeder, it can handle the thin and thick paper wiht high precision.

We provide 12 months warranty. During warranty, we provide free technical support and free normal spare parts for replacing, except for man-made damage.We can go to your country to debug machine when you have questions can not resolve,but you must pay 100usd/day to our engineer.

Look forward to long term cooperation with customers, we will make best service and aftersales service for all of our customers.

Contact Person: Mrs. Janey Su

Tel: 0086-13532845518

Fax: 86-769-23171677