|

Product Details:

|

| Name: | Book Case Making Machine | Function: | Gluing Positioning/Four Side Folding |

|---|---|---|---|

| Type: | Gluing Machine | Automatic Grade: | Automatic |

| Application: | Machinery & Hardware | After-sales Service Provided: | Video Technical Support |

| Highlight: | automatic hardcase maker,hardcase making machine,bookcase making machine |

||

Full Automatic Gluing Positioning Book Case Machine

Product Description

Full Automatic multi-functional gluing positioning machine is the best equipment to produce high-end world cover boxes, book boxes, hard book shell and other new products. Reasonable design, stable performance, equivalent to the international leading technology level. Adopt PLC programmable controller, HD Camera positioning system, Yamaha mechanical arm to positioning , touch human-machine interface. Realize the automatic paper, automatic gluing, automatic positioning box or grey board are completed at one-time finish. The machine production efficiency is several times higher than that of the traditional craft production, also have fault diagnosis display and alarm function, operation safety guarantee. Suitable for making the high-quality goods class electronic hard cover, jewelry box, and other high-grade packing gift box.

Product Advantage

1, the automatic shell machine generally adopts feida automatic paper feeding structure, the whole movement is pneumatic control, the structure is simple and reasonable.

2. The width adjustment of the stack platform and the paper platform adopts the center concentric adjustment, and the operation is simple without error.

3, the cardboard feeding table adopts linear guide rail, accurate.

4. There is an automatic stop device for the paperboard feeding table to reduce the rejection rate of good products.

5. The conveyor belt adopts high-power suction fan, which makes the paper transportation more stable and accurate.

6. The paper conveying and positioning system adopts imported high-precision photoelectric control, making the positioning of paper and paperboard more accurate and reliable.

7. The rear automatic four-side dismantling machine adopts unique automatic pressure Angle and blanking mechanism to ensure the qualified rate of finished products.

8. The automatic leather shell machine material collecting platform adopts the desktop stacking conveying and discharging, which is more convenient for material receiving.

Other Product Recommend

Jelly Glue / Hot Glue For Book Cover Machine

Technical Parameter

|

Paper Wrap Size (L=Length,W=Width) |

Widest(W) | 630mm |

| Narrowest(W) | 100mm | |

| Longest(L) | 820mm | |

| Shortest(L) | 120mm | |

|

Hard Book Case Size L=Length W=Width

|

Longest(L) | 800mm |

| Shortest(L) | 180mm | |

| Widest(W) | 450mm | |

| Narrowest(W) | 120mm | |

| Thickness of Paperboard(g/m2) | Thinnest(T) | 1.0mm -4.0mm |

| Thickness of Paper(g/m2,) | Range | 80g/m2-200g/m2 |

| Speed | ≤35pcs/min | |

| Air pressure | 6-8bar | |

| Voltage | 380V/50HZ | |

| Moter power | 18kw | |

| Heater power | 6kw | |

| Net Weight | 5800kgs | |

| Machine Overall Dimension | L6.5m×W4.3m×H2.2m | |

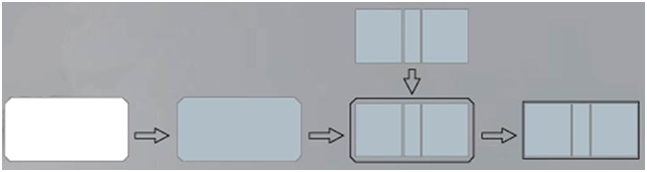

Product Flew

Our Services

1. Pre-Sales Service:

Inquiry and consulting support.

Sample testing support.

View our Factory.

2. After-Sales Service

Training how to install the machine, training how to use the machine.

Engineers available to service machinery overseas.

3. Warranty

We provide 12 months warranty. During warranty, we provide free technical support and free normal spare parts for replacing, except for man-made damage. We can go to your country to debug machine when you have questions can not resolve, but you must pay 100usd/day to our engineer.

Look forward to long term cooperation with customers, we will make best service and after sales service for all of our customers.

Contact Person: Mrs. Janey Su

Tel: 0086-13532845518

Fax: 86-769-23171677